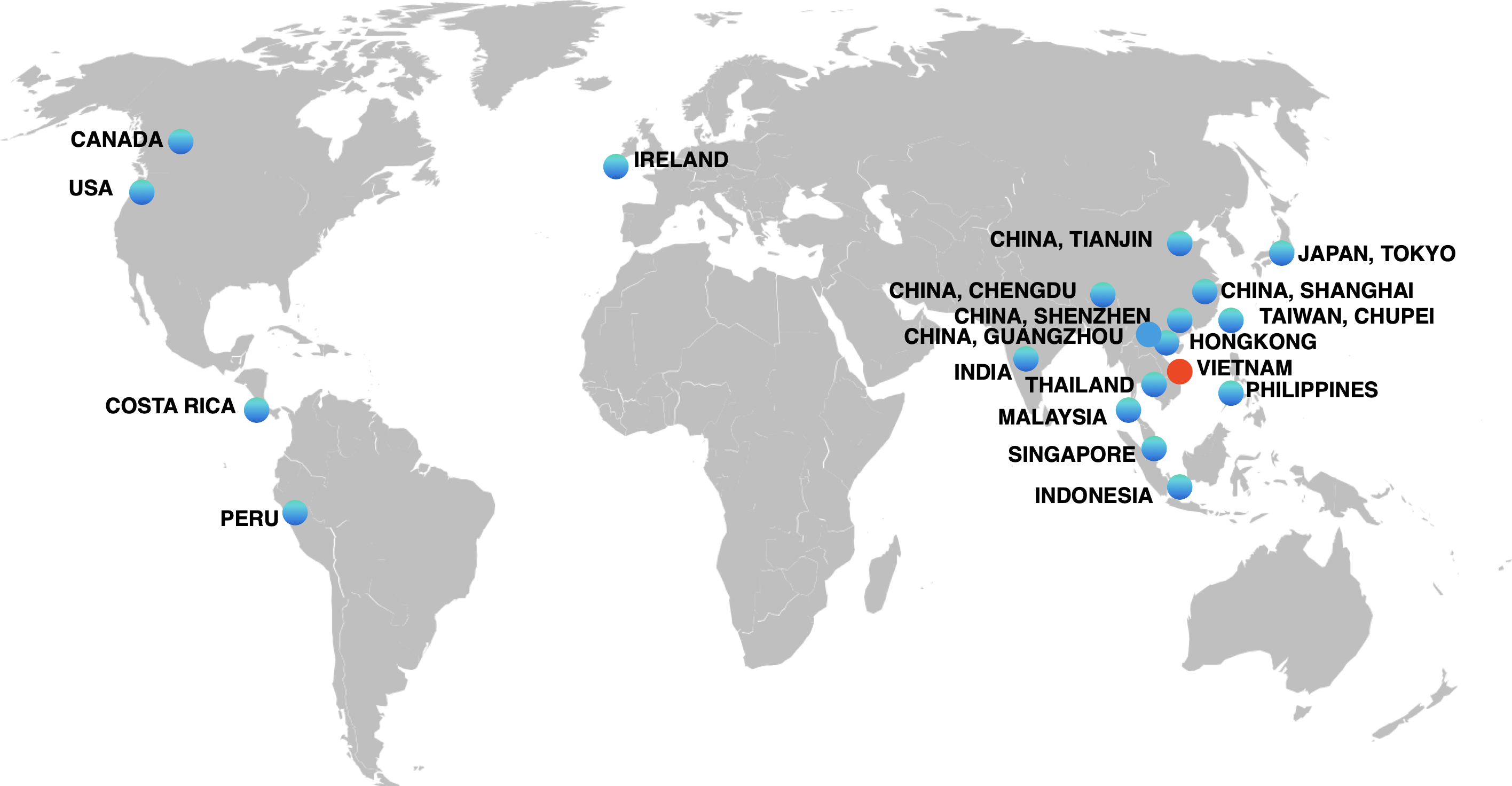

Ecopark – Your Trusted Global Product Sourcing Partner

Whether you’re developing a new product or already sourcing and want sharper pricing with stronger support, Ecopark makes it happen. Our end-to-end services ensure you get the right price, the right quality, and reliable on-time delivery—every time.

In-house QA Inspectors stationed at the factory, 365 days.

In-house QA Inspectors stationed at the factory, 365 days.